🌍 Introduction: Why Corrugated Boxes Dominate the Packaging World

Corrugated boxes are everywhere — from your latest online purchase to industrial shipments across the globe. Their popularity isn’t accidental. They’re strong, cost-effective, and versatile enough to package everything from electronics to frozen food.

Yet, not all corrugated boxes are created equal. Understanding the main types can help you pick the perfect packaging for your business needs.

🧱 Single-Wall Corrugated Boxes

This is the classic, most common type you see in daily shipping. A single-wall box has one layer of fluted paper sandwiched between two liners. It’s lightweight, economical, and suitable for everyday retail or e-commerce packaging.

If you’re a small brand shipping clothes, cosmetics, or stationery, single-wall is your go-to option. It balances cost and strength perfectly while keeping storage space minimal.

🏗️ Double-Wall Corrugated Boxes

When more protection is needed — for heavier or fragile items — double-wall cardboard comes into play. It uses two layers of fluting and three liners, giving it extra crush resistance and stacking power.

Factories often recommend double-wall boxes for bulk exports, electronics, or glassware. Though slightly heavier, they offer reliability during long-distance transportation, especially in humid conditions.

🧰 Triple-Wall Corrugated Boxes

Now we’re entering industrial territory. Triple-wall corrugated boxes are essentially the tanks of packaging — extremely rigid and durable. Built with three layers of fluting, they can handle machinery parts, automotive components, and other high-weight goods.

These are often used by large-scale packaging factories or exporters who need maximum strength and impact resistance. If your business deals with heavy cargo, triple-wall is your best investment in product safety.

🪵 Flute Types and What They Mean

Corrugated boxes aren’t just about walls; the flutes (the wave-like inner structure) play a big role in performance.

-

A-flute → thick cushioning, ideal for fragile goods.

-

B-flute → thinner, perfect for printing and retail packaging.

-

C-flute → general-purpose and widely used for standard shipping.

-

E-flute → compact, smooth surface, excellent for custom printed boxes.

Choosing the right flute type with your cardboard box supplier ensures the right balance between protection and presentation.

🧪 Testing Strength and Durability

A box’s strength isn’t just guessed — it’s measured. Key tests include the Edge Crush Test (ECT) and Bursting Strength Test, both of which indicate load-bearing and impact resistance.

Professional manufacturers always match these standards to your shipping route and storage conditions. It’s one of the main reasons why partnering with a reliable packaging manufacturer gives your brand an advantage in quality control and logistics safety.

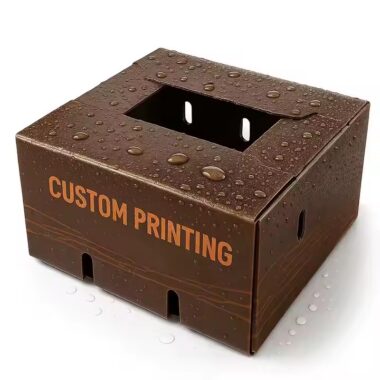

🎨 Beyond Protection: Design and Branding Potential

Corrugated boxes aren’t only about durability; they’re also a powerful marketing tool.

With modern offset and flexographic printing, even industrial boxes can feature full-color logos, QR codes, or eco-friendly messages. Many brands now turn plain cartons into a storytelling medium — blending strength with style.

🧭 Choosing What’s Right for You

If you’re unsure which type of corrugated box suits your product, start by identifying its weight, fragility, and shipping distance.

For lightweight retail goods, single-wall is enough.

For international exports, double-wall offers a safety margin.

And for heavy-duty or mechanical components, triple-wall guarantees performance.

Your supplier can also provide custom samples for testing before bulk orders — the best way to avoid surprises later.

🔚 Conclusion: Think Beyond a Box

A corrugated box is more than paper — it’s engineering.

Each layer, flute, and adhesive is designed to deliver strength, value, and sustainability.

By understanding these differences, you make smarter, safer packaging choices for your business — and your products arrive in the same perfect condition they left your factory.