📦 Product Highlights

✔ Lightweight & Cost-Effective: Perfect for mass production and easy transport.

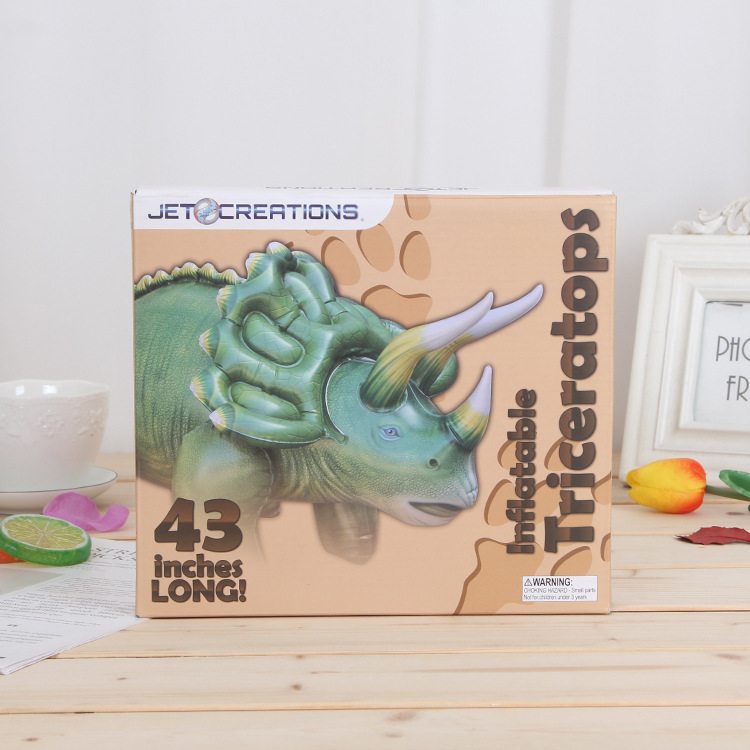

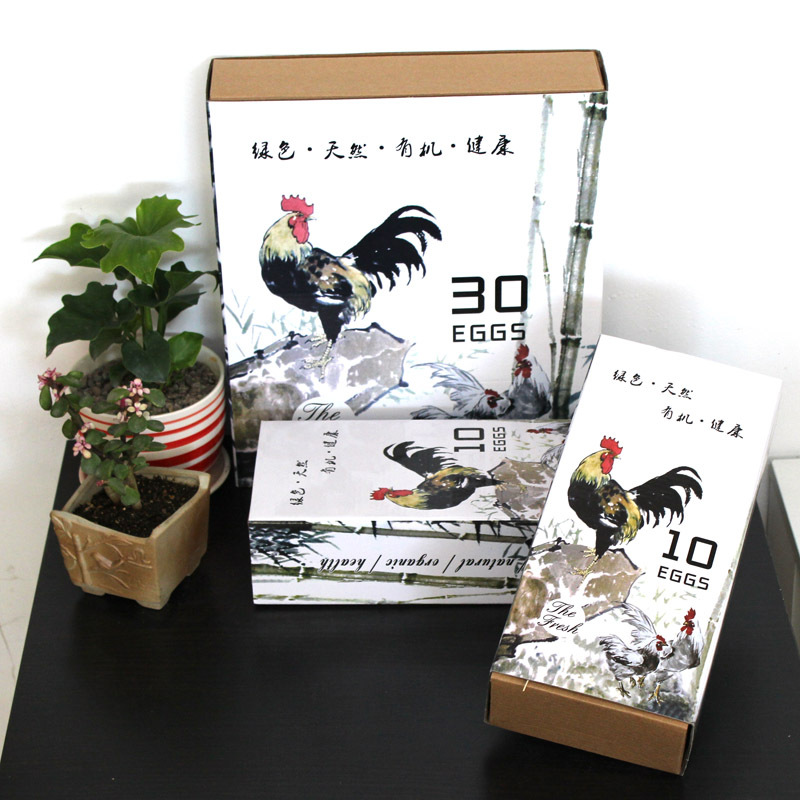

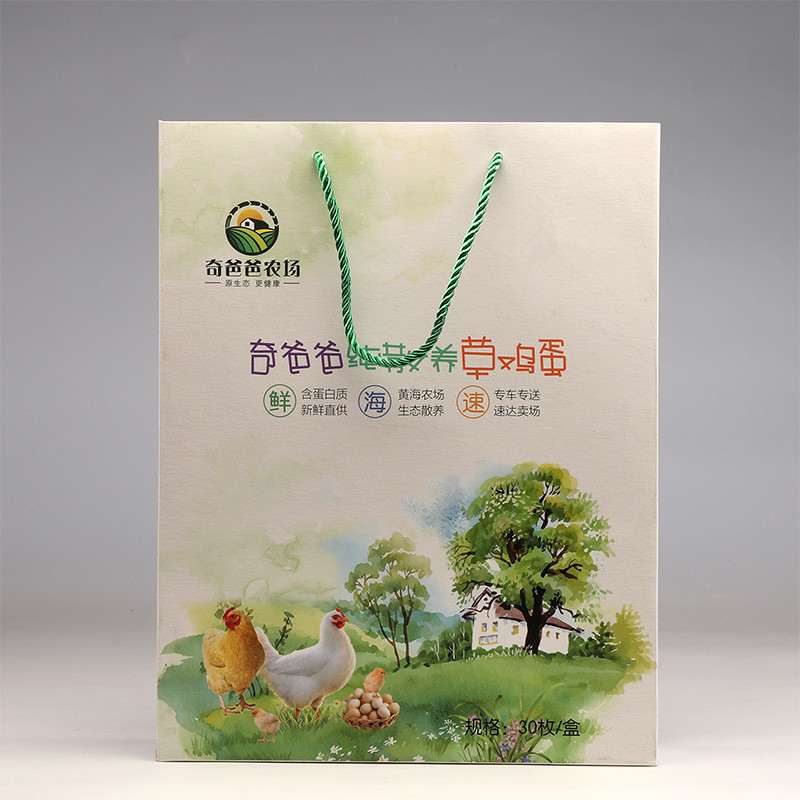

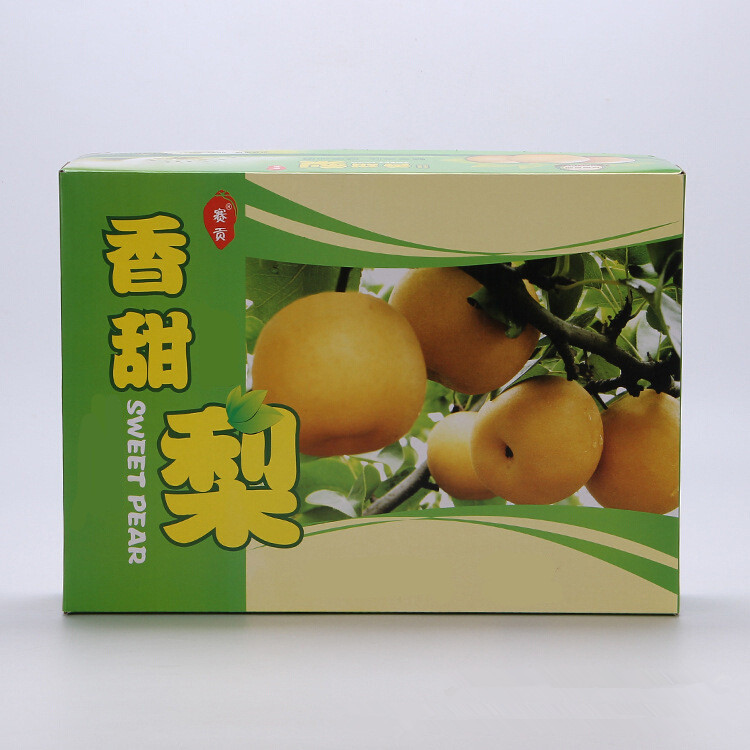

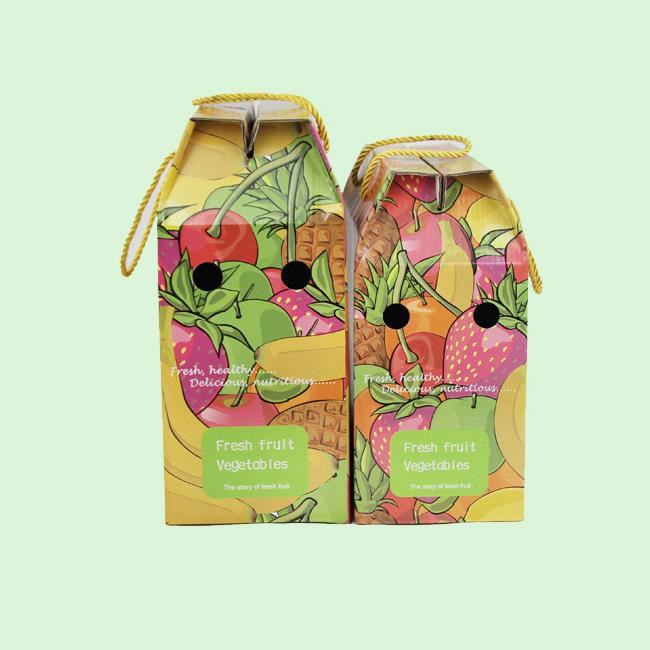

✔ High-Definition Printing: Offset and UV printing deliver vibrant colors and sharp images.

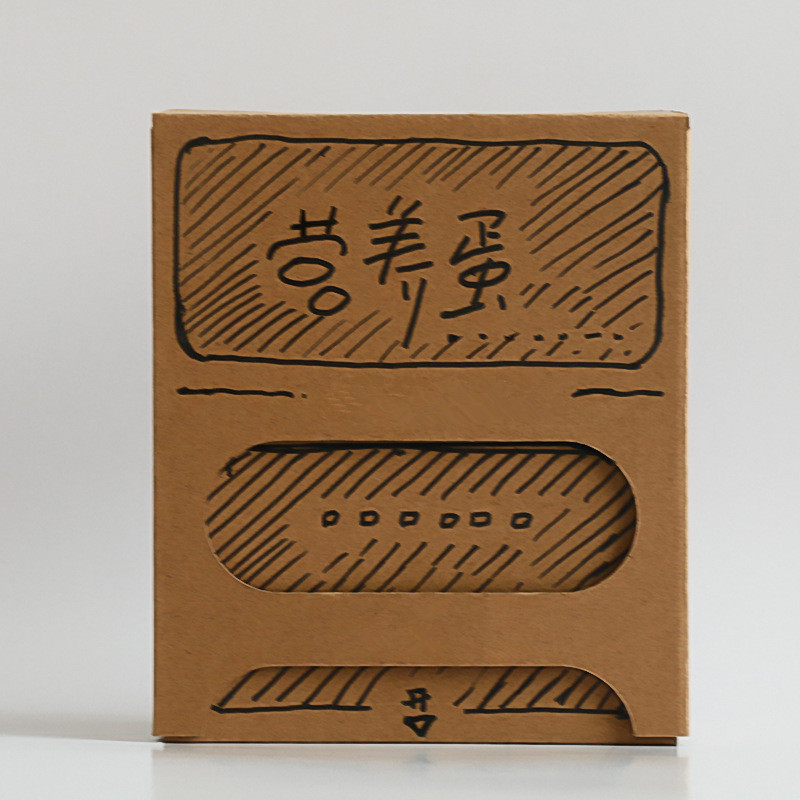

✔ Flat-Pack Design: Space-saving cartons that assemble quickly without glue.

✔ Customizable Structure: Tuck-end, crash-lock, and sleeve types for diverse products.

✔ Eco-Friendly Materials: Recyclable paperboard and biodegradable coatings available.

🖨️ Customization & Design Options

Every brand requires packaging that communicates quality and purpose.

We provide OEM/ODM folding cartons with flexible customization services:

-

Material Choices: SBS paperboard, kraft, art paper, and food-grade boards.

-

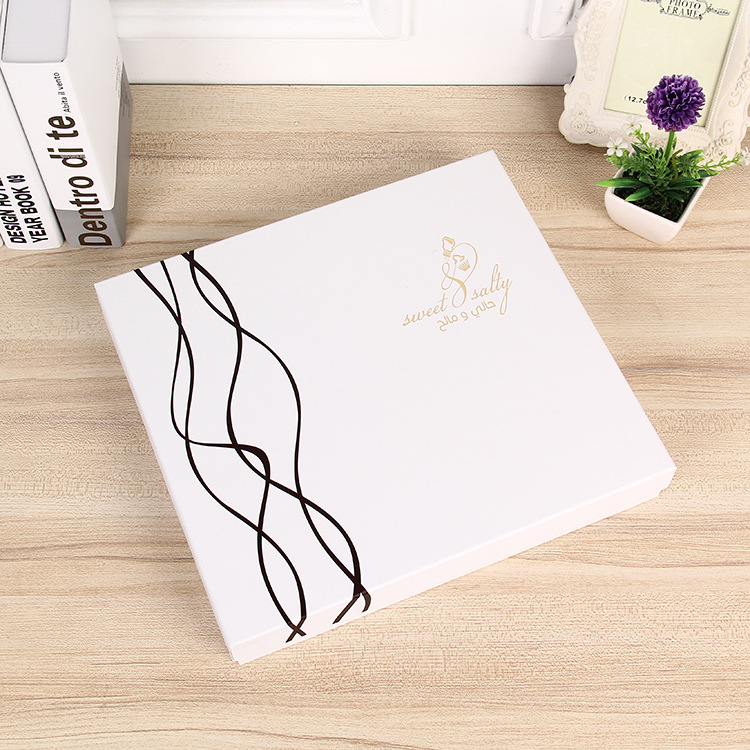

Printing: CMYK, Pantone, and foil printing for color consistency.

-

Finishing: Matte/gloss lamination, spot UV, embossing, debossing.

-

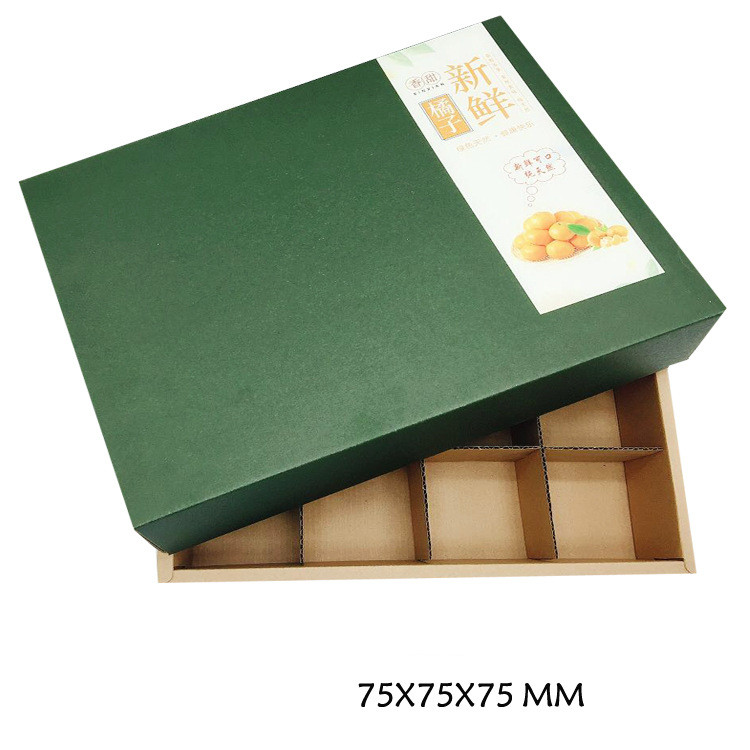

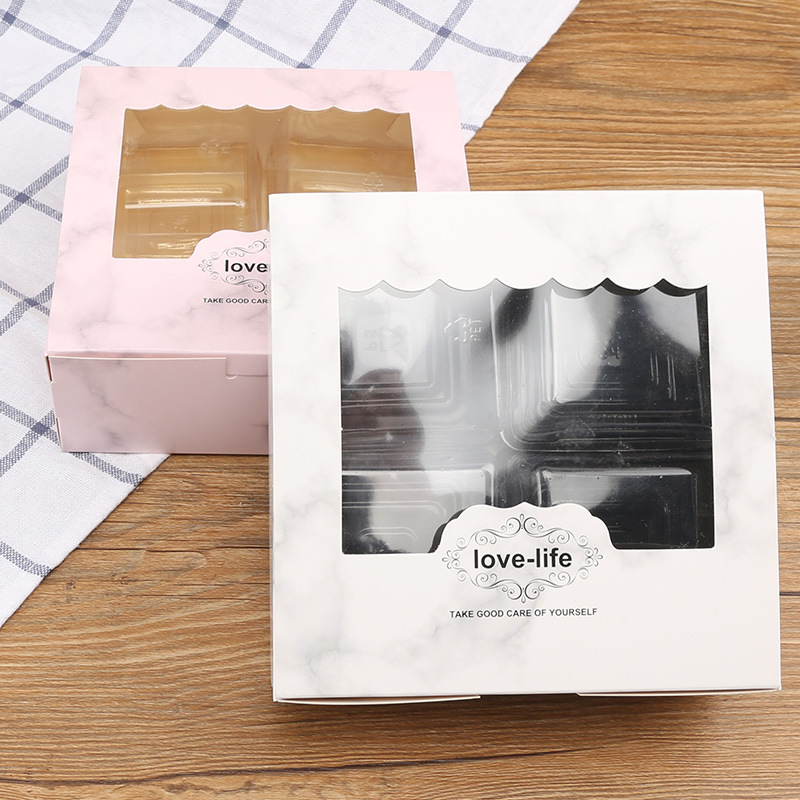

Box Styles: Tuck top, reverse tuck, crash bottom, display carton, or window patching.

-

Special Features: Die-cut shapes, tear lines, and hanger tabs for retail display.

For more structural options, visit our

Custom Cardboard Boxes

page to explore how a professional custom paper box supplier can tailor packaging to your brand identity.

🪵 Materials & Production Process

Our folding cartons are made from premium paperboard with thickness ranging from 250gsm to 500gsm.

Each sheet is printed, die-cut, folded, and packed flat to optimize space and minimize logistics cost.

We offer food-safe coatings, moisture-resistant laminations, and anti-scratch finishes to meet specific product needs.

For sturdier shipping-grade options, check out our

Corrugated Shipping Boxes factory,

designed for long-distance and heavy-load packaging.

📦 MOQ & Lead Time

The standard MOQ for folding cartons is 1000 pcs, with flexibility for trial runs or small brand launches.

Sample production takes 5–7 days, while bulk production usually finishes in 15–20 working days.

Our fully automated printing and cutting lines guarantee color accuracy and shape precision in every batch.

🏭 Why Choose Us

Choosing CardboardBox-Manufacturers.com means partnering with a professional folding carton factory that combines design innovation with production efficiency.

-

Integrated Manufacturing: In-house printing, cutting, and folding.

-

Fast Turnaround: Automated machinery for quick lead times.

-

Competitive Factory Pricing: Direct manufacturer—no middlemen.

-

Sustainable Practices: FSC-certified materials and water-based inks.

-

Global Supply Experience: Exporting to 60+ countries with reliable quality control.

💬 FAQs

Q1: What industries use folding cartons most often?

They’re widely used in cosmetics, electronics, pharmaceuticals, and food packaging due to easy customization.

Q2: Can you print both inside and outside of the box?

Yes. We provide dual-side printing to enhance the unboxing experience and brand storytelling.

Q3: Are folding cartons recyclable?

Absolutely. All our cartons use recyclable and biodegradable paper materials.

Q4: Do you offer window-cut or display styles?

Yes. We can add clear windows, die-cuts, or custom shapes for retail visibility.

🌍 Conclusion

Our folding cartons combine lightweight design, durable structure, and superior printing — perfect for brands seeking reliable, cost-effective paper packaging.

Whether you need 500 or 50,000 boxes, CardboardBox-Manufacturers.com provides full customization, professional printing, and eco-conscious materials that deliver performance and style together.